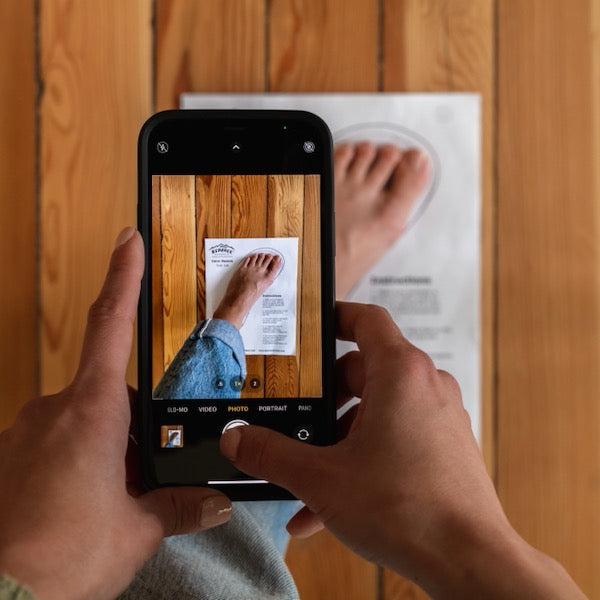

Background: Bedrock was born in the woods and rivers of Northern California back in 2011 when two fresh-out-of-college geologists began a life altering journey to design and build truly adventure-capable sandals. 7 Years later the team began crafting something entirely new for the sandal off-season. Read more about the lengthy & rewarding process of designing Bedrock’s first shoe.

Back in 2018, on the train ride home from a fall bike tour, and with the relocation of Bedrock from California to Missoula, MT on the horizon, the idea for an actually-capable clog was born. It would be a new piece of Bedrock footwear that combined much of what we’d mastered in our sandals, but in a closed-toe package formulated for the sandal off-season. We began making early prototypes in our California workshop, borrowing the soles from our sandals and stitching on synthetic fabric for uppers. We did our best to make the fabric three-dimensional without the traditional lasting process, dissecting other clogs and shoes to see how they were constructed. We ended up with a functional clog-like thing to slip our feet into, but they sure weren’t pretty. It was in those early days that we discovered the significant difference between making our award-winning sandals and a modern clog we could be proud of. We needed to learn how to make shoes.

Early development photo from our Bedrocks previous HQ in Richmond, CA circa 2019.

Some soggy winter miles were logged on those protos, but the idea was shelved as we packed up our HQ, launched our PRO II models, and began to navigate the challenges of an ever-evolving pandemic.

The summers in Montana turn out to be just as short as they are sweet, and so rounding the corner on our first year living in the Rockies, right about when the leaves fell, we started to get the itch to figure out a Bedrock clog once and for all. We wanted to keep the freedom-feel of our sandals, but our toe-socks were only taking us so far when the temps began to really dip. We were hearing the same from other Bedrockers, and we became obsessed with cracking the closed-toed code.

Fall in Montana - near Glacier National Park.

Winter in Missoula, MT - on some trails just north of Bedrock HQ.

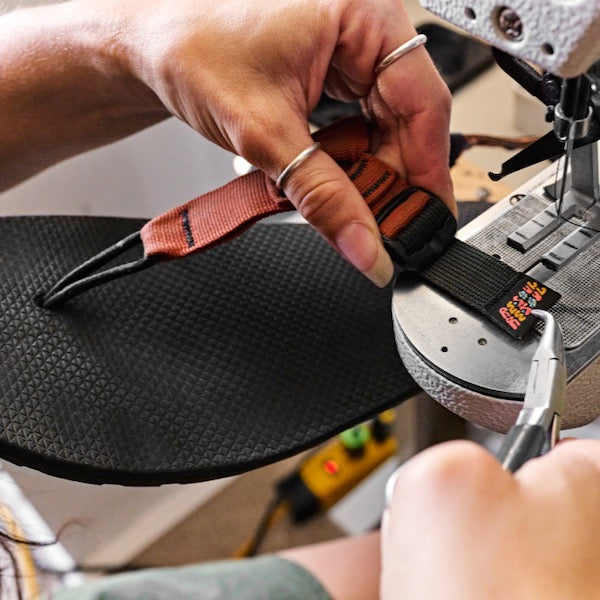

This time around, we got serious about our knowledge gaps and enlisted the help of some footwear experts who could teach us the intricacies of making a real-deal shoe and where in the world it could be built right. For two more years this became our daily mission: designing, having samples made, tearing them apart, putting them on testers’ feet, getting feedback, altering the design, switching out materials, reconfiguring, and on and on. We visited our factory in South Korea, a high-end outfit that specializes in manufacturing smaller volume, quality-intensive athletic footwear. The team at the factory went all-in with us, innovating their manufacturing to make our clogs better than first imagined. After dialing in all the last details, the Mountain Clog — as we’d been calling the earliest versions on romps around the Sierra — was finally ready.

Mountain Clog Design - More refined and ready for sampling at the factory.

New Mountain Clog Sole Development V1.

Nick, Bedrock Co-Founder, ended up going to town on this sample with a box cutter to make the lugs more agile and cut out weight. These rubber hacks saved close to 1oz per Clog.

Photo spread of Bedrock's visit to the factory in S. Korea - dialing in manufacturing specifics with the team prior to production.

Our Next Big Leap

We don’t want to say it was inevitable, but building a uniquely adventure-ready clog just felt right for our Bedrock journey. It’s a natural progression from sandal to shoe, a hybrid of sorts with its open heel and ability to wear with or without socks. We’d seen other modern clogs too, but they were either too casual or too flimsy for the type of fun we like to have. We wanted something, like our sandals, that you could casually slip on but also charge hard in. So we made sure to incorporate a wide and natural toe-box, zero drop, and our three point sandal strap design that provides an unusual amount of adjustment and security not found in other clogs. We also brought in features like a climbing rubber toe cap for added protection plus leather and synthetic upper options for any occasion. And you know we had to give it that good Bedrock ground game: the Vibram® megagrip outsole pattern is totally new and versatile, designed to provide solid footing on loose gravel & shop floors alike.

The Bedrock Mountain Clog - In our synthetic Clarino® microfiber gray color.

Defining the long list of what the Mountain Clog is made for seems impossible — so we’ve left it to you. We’ve used it as a daily driver for bike commutes & bikepacking trips, as a fall day hiker in Glacier NP, skateboarding suburban asphalt, tinkering in the garden, and even thru-hiking the AZT (800 miles). Work in ‘em. Bag peaks in ‘em. Even dance in ‘em at a granola-fancy wedding.

Day hiking this last fall in the hills above town.

Car camping on the banks of the Flathead River.

Dr. Meg Fisher riding in clogs around Missoula.

Mountain Clogs make a perfect match for that first dusting of snow on your favorite trail.

Bedrock customer Nathan logged 800+ miles on a Mountain Clog proto while thru-hiking the AZT.

We couldn’t be more excited to share our latest labor of love with you. Born at the cross-roads of cool-weather comfort and adventure, we poured all our best sandal DNA — plus a lot of heart and soul — into these first-ever closed-toed schist kickers. They’re made juuuust right for you to go hard and take it easy. #shoesforsandalpeople #saygoodbyetothesandaloffseason #getcloggedup

The entire Mountain Clog lineup - available now!

Mike Nicholson

March 09, 2023

Hey guys! The clog is such a hit with me I’m ordering a second pair. Tell Nick hello.( I’m the older guy from the church in Oakland who now lives in Virginia. )If any of you are interested in the AT or hitting the bike trails around exotic Farmville, just remember you’ve got a place to stay.👋🏻